A tractor hitch is a mechanism used to attach implements or attachments to a tractor.

There are several types of tractor hitches, each with its own unique features and advantages.

Whether you are looking for a simple three-point hitch or more advanced multi-function hitches, there is sure to be one that fits your needs.

In this article, we will take a closer look at some of the most common types of tractor hitches on the market today.

Types Of Tractor Hitches

There are 5 main types of tractor hitches that are commonly used today: three-point hitch, drawbar hitch, quick hitch, fifth-wheel hitch, and PTO hitch.

Understanding the differences between these hitches can help farmers and ranchers make the best choice for their equipment and needs.

Three-Point Hitch

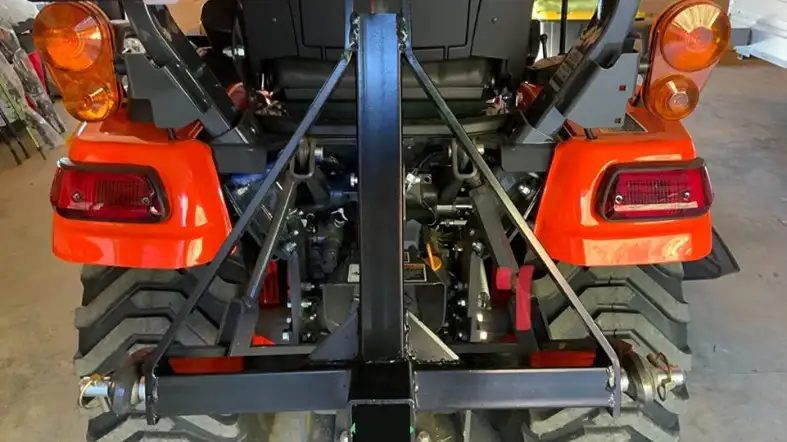

The three-point hitch is the most common hitch found on tractors and is used for attaching a wide variety of implements, such as plows, mowers, and cultivators.

It consists of three points of attachment: two lower arms that attach to the tractor frame and a top link that connects to the implement.

The three-point hitch allows for easy attachment and detachment of implements, as well as adjusting the implement’s height and angle.

Drawbar Hitch

A drawbar hitch is a simple and versatile hitch that is used for attaching a trailer or other implements to the back of a tractor.

It consists of a horizontal bar with a hitch ball at one end and a pin at the other end that attaches to the tractor frame.

The drawbar hitch is typically used for hauling heavy loads, such as hay bales or large equipment, and is often used in conjunction with a ballast box for added weight and stability.

Quick Hitch

A quick hitch is a specialized hitch that allows for easy and efficient attachment of implements to a tractor.

It consists of a frame that attaches to the tractor’s three-point hitch, with a series of pins and hooks that align with the implement’s attachment points.

The quick hitch allows the operator to easily attach and detach implements without leaving the tractor seat, making it an ideal option for farmers with multiple implements.

Fifth Wheel Hitch

A fifth-wheel hitch is a heavy-duty hitch that is used for attaching large trailers, such as livestock trailers or grain trailers, to a tractor.

It consists of a large, horizontal plate that attaches to the tractor’s frame, with a vertical pin that extends upwards and connects to the trailer’s fifth wheel.

The fifth wheel hitch is designed to handle the weight and forces of large trailers and is typically used on tractors with a high horsepower rating.

PTO Hitch

A PTO (Power Take-Off) hitch is a specialized hitch that is used for attaching implements that require power from the tractor’s engine, such as a rotary tiller or wood chipper.

It consists of a shaft that extends from the tractor’s PTO drive system and connects to the implement’s power input.

The PTO hitch allows the implement to operate using the tractor’s engine and is typically used for implements that require a lot of power.

What Are The Different Categories Of Tractor Hitches Available?

There are 5 categories of tractor hitches which are,

Category 0

The most common category is category 0, which refers to smaller tractors with lift arm pins that measure 5/8 inch in diameter.

Usage

- This category is ideal for lawn and garden tractors, as well as compact or sub-compact tractors.

- They can be used for a variety of tasks, such as plowing, tilling, and hauling.

- They are also often used for towing implements, such as trailers or mowers.

Pros

- They are extremely easy to use as they do not require any special tools or equipment in order to be attached to a tractor.

- They are very affordable.

- They are widely available and one should be able to find a hitch that meets your needs without having to search far and wide.

Cons

- Category 0 tractor hitches have a lower weight limit than other types of hitches.

- Unlike other types of hitches, they cannot be used with larger implements, such as mowers and balers.

- They tend to be more expensive than other types of hitches.

Category 1

Another category is category 1, which typically refers to larger tractors that have lift arm pins measuring up to 2 inches in diameter.

Usage

- These tractors are often used for heavier loads and more powerful operating conditions, making them ideal.

- Category 1 tractor hitches are designed for use with small tractors.

- They are typically used for attaching implements such as plows, and cultivators, and mowers to the tractor.

Pros

- Category 1 tractor hitches are extremely durable and can withstand a wide range of operating conditions.

- They are also very versatile and can be used with a variety of different types of implements.

- They are generally less expensive than other types of tractor hitches, making them an affordable option for many farmers and gardeners.

Cons

- One potential drawback of category 1 tractor hitches is that they may not be able to support very large or heavy implements, such as balers and plows.

- Another potential drawback is that these types of hitches can sometimes be difficult to install or remove from the tractor, especially if you don’t have the right tools or equipment.

Category 2

Category 2 is one of the largest categories of tractor hitches.

These hitches are typically found on larger tractors and can support heavier implements than smaller categories like 0 and 1.

The lift arm pin diameter for a category 2 hitch ranges from 1″ to 2″, making it ideal for heavy-duty lifting tasks.

Usages

- They are commonly used for farming applications such as plowing and discing fields.

- They are also used for other tasks such as landscaping and towing heavy equipment.

Pros

- It can support heavier implements than smaller categories.

- This makes it ideal for large-scale farming and other heavy-duty tasks.

- The larger lift arm pin diameter provides extra stability, making it less likely to break or bend under heavy loads.

Cons

- One potential disadvantage of using a category 2 tractor hitch is that it requires a larger tractor with more powerful lift arms, which can be more expensive to purchase and maintain.

- Heavier implements may require additional weight in order to prevent the tractor from tipping over. This could increase your costs for fuel and maintenance over time.

Category 3

A category 3 hitch is a type of tractor hitch system that is typically found on larger tractors, such as those used for agricultural and industrial applications.

This type of hitch features lifts arms with pins that have diameters ranging from 5/8 inch to 2 inches, allowing it to support heavier implements and equipment than smaller categories.

Usages

- The 3-point hitch categories are used to indicate the size and weight of implements that can be attached to a tractor.

- Smaller categories like 0 and 1 tend to be found on smaller tractors, such as lawn tractors, compact tractors, and sub-compact tractors.

Pros

- It provides a versatile and efficient way to attach and use various types of implements, from small lawn care tools to larger farming equipment.

- The lift arms on most tractors are sturdy enough to handle heavier loads without the risk

Cons

- One potential drawback of the 3-point hitch system is that, as the category number increases, it may require more power and a stronger tractor to support larger, heavier implements.

- The size and weight of the implements can make them more difficult to maneuver and control when attached to a tractor.

Category 4

The 3-point hitch category 4 is designed for larger, heavier implements and tractors.

This type of hitch has a lift arm pin diameter of 2 inches or greater, allowing it to accommodate larger and heavier implements such as plows, tillers, and manure spreaders.

Such implements require the strength and stability provided by category 4 hitches.

Usages

- These larger and more robust hitches can handle the weight and force required for types of agricultural tasks, making them a popular choice among serious farmers and other agricultural professionals.

- They are compatible with a wide range of implements, allowing farmers to customize their tractors based on the specific tasks they need to accomplish.

Pros

- Robust and sturdy construction.

- Can withstand heavy loads and high forces.

- Compatible with a variety of agricultural implements.

Cons

- More expensive than other types of hitches

FAQs about Types Of Tractor Hitches

How Do You Decide Which Type Of Hitch Is Best For Your Needs?

There are a few key factors to consider when choosing the right type of hitch for your needs.

One of the most important is the size and weight of the implements you will be using with your tractor.

Smaller, lighter implements like plows, mowers, and spreaders typically require a smaller category 3-point hitch, such as a 0 or 1.

Larger, heavier implements like disc harrows and rototillers will likely require a larger category, such as 2 or 3.

How To Maintain Your Tractor Hitch?

There are several steps that you can take to maintain your tractor hitch and keep it in good working condition.

Make sure that the lift arms and other components of the hitch are properly aligned, so that they work together smoothly and efficiently.

You should also regularly check for any signs of wear or damage, such as cracks, rust, or dents, and make any necessary repairs as soon as possible.

What Are The Common Problems With Tractor Hitches And How To Solve Them?

Tractor hitches are an essential part of any tractor, allowing it to attach a wide range of different implements and tools for various purposes.

However, there can be a number of common problems that arise with these hitches, such as worn or damaged parts, improper setup, and alignment, or even incorrect attachment to the tractor itself.

Conclusion

There are various types of tractor hitches that can be used for a variety of purposes.

From the three-point hitch, which is commonly used for attaching implements such as plows and mowers, to the quick hitch, which allows for easy and efficient attachment of implements, each type of hitch has its own unique set of features and benefits.

No matter which type of tractor hitch is used, it is important to ensure that it is properly attached and used according to the manufacturer’s guidelines in order to ensure the safety of the operator and the effectiveness of the implement being used.