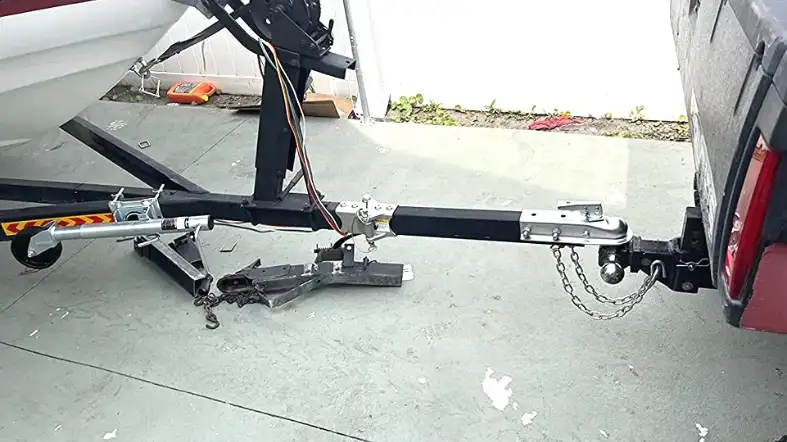

Trailer hitch couplers are a vital component of any towing setup, as they connect the trailer to the tow vehicle.

However, like any mechanical component, they can experience problems over time.

In this blog post, we’ll take a closer look at some of the most common issues that can arise with trailer hitch couplers, including rust and corrosion, loose or missing pins, and misaligned couplers.

What are the common trailer hitch coupler problems?

The most common problems that can arise with trailer hitch couplers include:

Rust and corrosion:

Rust and corrosion can occur on the metal parts of the coupler, such as the hitch ball socket, the locking mechanism, and the pins.

This can cause the metal to weaken and become brittle, making it more likely to break or fail during towing.

Signs of rust and corrosion include discoloration of the metal, flaking or peeling paint, and a rough or pitted surface.

Loose or missing pins:

The pins that hold the coupler to the trailer can become loose due to vibration or can fall out completely.

When this happens, the coupler can become disconnected from the hitch ball, which can cause the trailer to come loose while towing.

Signs of loose or missing pins include the coupler being able to move or rotate on the hitch ball, or the coupler falling off the hitch ball entirely.

Misaligned couplers:

If the coupler is not properly aligned with the hitch ball, it can cause the trailer to be pulled at an angle, which can lead to dangerous driving conditions.

This can be caused by a worn or damaged hitch ball, an improperly installed coupler, or a bent or twisted hitch ball socket.

Signs of a misaligned coupler include the trailer pulling to one side, the coupler being difficult to connect or disconnect, or the coupler making a loud or grinding noise while towing.

Worn Out Or Damaged Parts:

Over time and with heavy use, the moving parts of the coupler can become worn out or damaged.

It can make it difficult or impossible to connect or disconnect the trailer.

This can include worn or damaged latch or lock mechanisms, bent or twisted hitch ball sockets, or corroded or rusted pins.

Signs of worn or damaged parts include difficulty connecting or disconnecting the trailer, or the coupler falling off the hitch ball while towing.

Latch or lock mechanism not functioning properly:

If the latch or lock mechanism of the coupler is not functioning properly, it can cause the coupler to become disconnected from the hitch ball while towing.

This can lead to dangerous driving conditions.

This can be caused by a worn or damaged latch mechanism, a corroded or rusted lock mechanism, or a bent or twisted hitch ball socket.

Signs of a malfunctioning latch or lock mechanism include difficulty connecting or disconnecting the trailer, the coupler falling off the hitch ball while towing, or the coupler coming loose while towing.

Improper installation:

If the coupler is not installed properly, it can cause the coupler to become disconnected from the hitch ball while towing, which can lead to dangerous driving conditions.

This can be caused by not installing the coupler according to the manufacturer’s instructions, using the wrong size coupler, or not properly securing the coupler to the trailer.

Signs of improper installation include difficulty connecting or disconnecting the trailer, the coupler falling off the hitch ball while towing, or the coupler coming loose while towing.

How To Prevent Trailer Hitch Coupler Problems?

Here are some preventive measures that can help keep your trailer hitch coupler in good working condition:

Regular cleaning and maintenance:

- Keeping the coupler clean and dry can help prevent rust and corrosion from developing.

- To clean the coupler, use a damp cloth to wipe down the metal parts of the coupler, and dry them thoroughly.

- Use a rust inhibitor or paint to protect the metal from the elements.

- Applying a protective coating on the coupler, such as wax or oil can also help slow down the process of rust and corrosion.

- Additionally, it’s important to lubricate the moving parts of the coupler, such as the latch or lock mechanism, to ensure smooth operation and to prevent wear.

Regular inspections:

- Check the coupler for signs of wear or damage on a regular basis.

- Look for rust, corrosion, loose or missing pins, and misaligned couplers.

- Make sure the latch or lock mechanism is functioning properly.

- This can be done before each use, or at regular intervals, such as every 6 months, depending on how often the trailer is being used.

Proper usage and storage:

- Use the coupler correctly and only for the weight and size of trailer that it’s rated for.

- This will prevent overloading the coupler which can cause it to fail. When not in use, store the coupler in a dry place to prevent rust and corrosion.

- Cover the coupler with a weatherproof cover or keep it in a dry place such as a garage or shed.

Adjustment and replacement:

- When necessary, adjust or replace the coupler parts to ensure proper alignment and functionality.

- This can include replacing worn or damaged parts such as the latch or lock mechanism,

- Or adjusting the alignment of the coupler to ensure a proper fit with the hitch ball.

Proper Installation:

- Make sure the coupler is installed according to the manufacturer’s instructions and using the proper size and type of hitch ball.

- Improper installation can lead to misaligned couplers and other problems.

Proper Towing Technique:

- Follow the proper towing technique while towing the trailer, and make sure the coupler is properly connected and locked before towing.

- This means checking that the coupler is securely fastened to the hitch ball, that the latch or lock mechanism is engaged and that the pins are securely in place.

- Additionally, it’s important to ensure that the coupler is the correct size and weight rating for the trailer being towed.

- Make sure that the hitch ball and coupler are the same size.

FAQs on Trailer hitch coupler problems

How Can I Prevent Rust And Corrosion On My Trailer Hitch Coupler?

To prevent rust and corrosion on your trailer hitch coupler, you should clean and lubricate it regularly, and keep it covered when not in use.

What Should I Do If My Trailer Hitch Coupler Is Not Properly Latching Or Aligning?

If your trailer hitch coupler is not properly latching or aligning, you should check that the locking mechanism is functioning properly.

Make sure that the coupler is properly aligned with the hitch ball.

If the problem persists, it may be necessary to have the coupler inspected or replaced by a professional.

What Are The Signs Of Wear And Tear On A Trailer Hitch Coupler?

Signs of wear and tear on a trailer hitch coupler include difficulty latching or unlocking the coupler, looseness or play in the coupler, and visible damage or wear on the locking mechanism.

Can I Fix A Damaged Trailer Hitch Coupler Myself?

It depends on the extent of the damage.

Minor issues, such as rust or worn-out lubrication, can be fixed with proper cleaning and lubrication.

However, if the damage is more severe, such as a broken locking mechanism, it is best to have it inspected and repaired by a professional.

Can An Old Or Worn Out Coupler Cause Safety Issues While Towing?

Yes, an old or worn out coupler can cause safety issues while towing.

A worn out coupler may not latch properly, allowing the trailer to detach from the tow vehicle while in motion.

This can be extremely dangerous and can lead to serious accidents.

It is important to regularly inspect and maintain your coupler to ensure that it is in good working condition.

Wrap Up

Trailer hitch coupler problems can range from rust and corrosion to wear and tear on the locking mechanism and improper latching or alignment.

These issues can not only make towing difficult, but they can also be a safety hazard.

To prevent rust and corrosion, it’s important to clean and lubricate the coupler regularly and keep it covered when not in use.

Regular inspection and maintenance of your coupler can help ensure that it is in good working condition and keep you and your trailer safe while on the road.