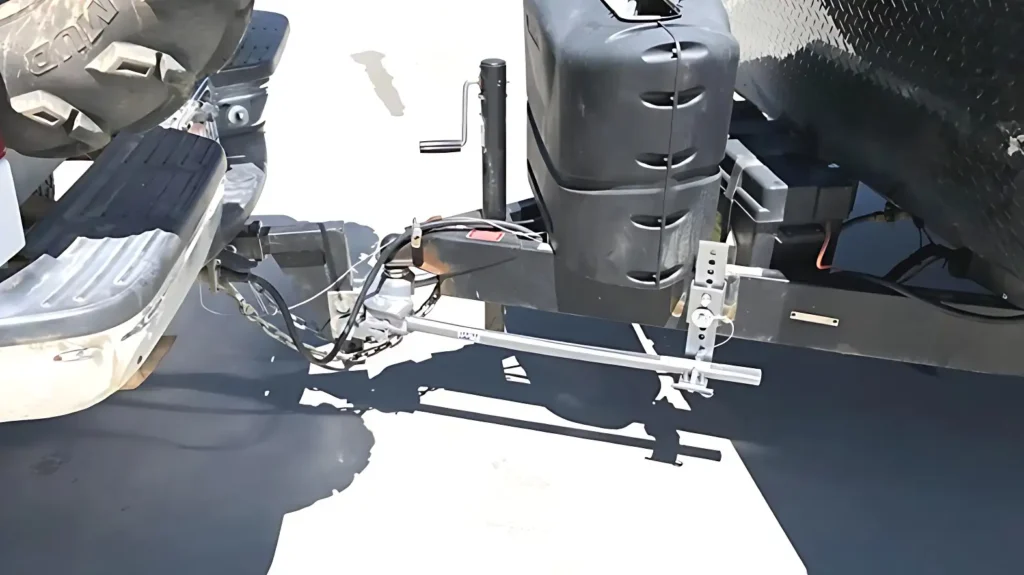

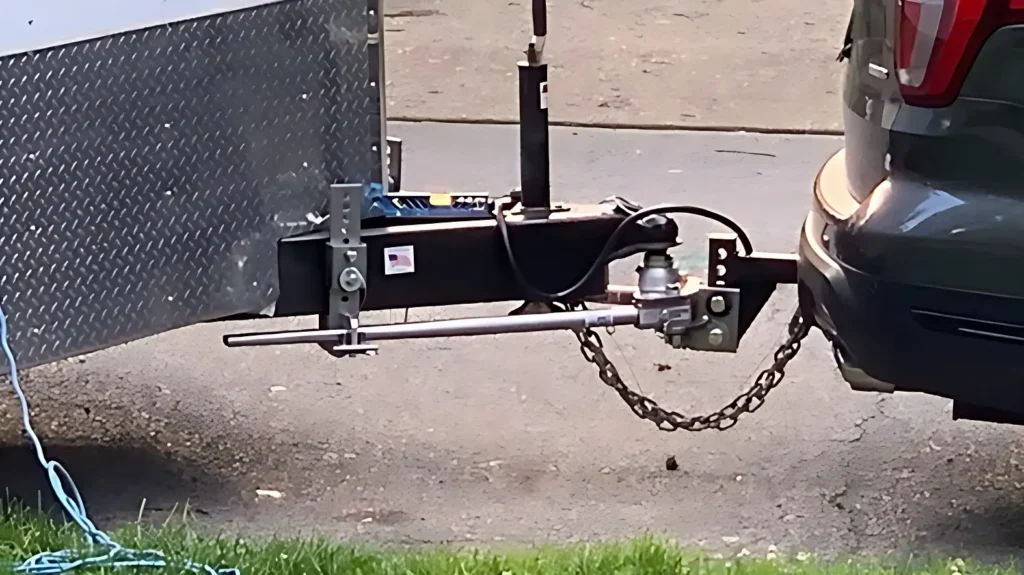

In the modern hitch market, the Husky centerline is among the most reliable and robust options available.

It knows how to get the job done irrespective of the circumstances and vehicle match-up.

However, it doesn’t come without its share of problems, and a few common Husky Centerline Hitch Problems may occasionally disturb you.

Therefore, it is reasonable to assume that you are familiar with how to identify, prevent, and address typical issues related to the Husky centerline hitch.

Thus, read on to get the issues identified and addressed.

The major husky centerline hitch problems:

The major and frequently faced issued by the Husky Centerline Hitch users are shearing the hitch pins, unreasonable and irritating noise, hitch breakage, the unusual operation of the anti-sway feature, etc.

What’s more, you may occasionally experience other minor issues coupled with those mentioned here.

The following paragraphs explain the ins and out for you lucidly.

1. Unreasonable and irritating noise:

This happens mostly with the sway control hitches.

But, we assure you, it may be the single most annoying thing that you may have to deal with a husky centerline hitch.

Out of all the husky centerline hitch problems, you would want to get rid of it as early as possible.

Once you notice it, it starts to become increasingly noisy as you use it.

However, it is not too uncommon to notice a fair amount of banging and cracking with any weight distribution hitch.

But the trouble begins when the noise appears to be getting louder and happening more often than the others.

What causes the problem:

It happens, as anybody’s guess, due to the excessive friction of the sticking points.

In fact, the last brackets are supposed to cause some friction to have the sway control system balanced.

Last brackets tend to create the most racket since when you force the bars into the brackets, they get stuck, and then pop free.

But when the noise gets excessive, it is not alright.

Moreover, unrestricted and uncontrolled friction is very often linked to failed sway control and accidents on the roads.

Apply Lubricant:

You have the solution staged on your mind already, don’t you?

You are probably thinking of picking up the lubricant present in your garage right away and applying it to the sticking points.

Or, if you don’t have a lubricant at hand, you are probably scrolling on any e-commerce site to place your order for a lubricant.

Well, you are right there – that’s what you have to do here.

Bearing and axle grease can be the ideal pick here.

You can use something like the full synthetic grease of Valvoline, or the premium wheel bearing grease of Timken.

Put some lubricant on the areas that are sticking together.

Also, for smooth bar installation, apply some lubricant to the surface of the lift bracket.

Lubricate the surface of the lift bracket that holds the bars in place.

Additionally, you can lubricate the hitch ball.

Loosen the hitch:

You may even notice the bars getting trapped on the bracket!

At their tightest, the bars would become jammed in the bracket when turning.

It will leave you with a 20-degree off-center steering wheel.

It could be a horrible experience until you loosen the hitch.

Use Teflon patch:

A very essay-to-utilize and quick solution is to use the Teflon patches.

Famously, Equalizer offers for sale the best Teflon patches.

You have to apply this patch over the surface of the L bracket.

Trust us, it does a miracle! It will immediately cut down on the friction that causes sticking and crackling sounds.

The Bar Imbalance:

Sometimes the bars you are using may not be the ones your hitch asks for.

For instance, 600-800 bars may not be suitable for your hitch, even if the specifics say so.

As it doesn’t fit right, we often end up, for correct assembly, tensioning them quite firmly.

This is where things start to go wrong!

So, you may check by switching between the bars.

For instance, if you are currently using 600-800 bars, upgrade yourself to 800-1200 bars.

It will require a full reset of the entire hitch.

Once you do this, there will be much less tension for the new bars.

They will give you identical weight distribution and sway qualities.

However, the noise will no longer be there.

2. Shearing the hitch pins:

This particular sort of problem almost resembles the one discussed above.

The only difference here is that rather than causing irritating noise, it out the hitch at risk of damaging wear and tear very fast.

The problem:

When the tension in the sticking points and bar connection is too high, it might wreck the hitch’s bodily integrity.

You can get the sensation that the structure is ripping the hitch pins out of the bars.

Even after altering the bars and pins, the system may still deform.

What do you do then? Don’t panic, the solution is a breeze!

The solve:

When this happens, applying lubricant may not be of any use.

So, we don’t recommend that. Rather contact the manufacturer or any professional and don’t make the hitch operation in the meantime.

The manufacturer will most likely ask you to opt for the new pins and bars.

However, at first, simply changing the hitch pins may do the job.

Once you have changed the bars and pins, the issue should resolve.

To maintain efficiency, make a habit of applying grease to the saddle a habit.

And, if the system continues to trouble you anyway, you will have to get the upgraded bolts.

For instance, upgrade yourself from grade-6 bolts to grade-8 bolts.

Grease is also essential to be applied to the cam that presses on the piston.

It will make a good hitch, although a somewhat heavy one.

3. Centerline’s Anti-Sway Mechanism:

You have set every piece of equipment in place and are all set to start hauling.

Wait, the excessive sway won’t let it make it far!

It is now normal to wonder what can possibly go wrong!

Well, it doesn’t need much to mess up the whole system.

The cause of the problem:

Always keep in mind that the Centerline’s anti-sway mechanism works differently compared to other hitches.

It is completely independent of the WD bars’ downward pressure.

At the trunnion end of the bars, the pistons minimize sway by compressing the Belvedere washers within the hitch via a cam action.

So, not setting up the cam rightly will cause too excessive sway to control the vehicle.

The bars may get unhooked from the hitch and move side to side.

It will leave you with very little resistance. You may even find latching the bars challenging.

The solve:

It is normal for the metal to wear against one another.

So, obviously, it necessitates the addition of shims or washers to prevent metal-on-metal contact.

It is recommended by the handbook that you place a shim on the side where the trunnion is closest to the pressure plate.

You can only do this if you can comfortably slide a Husky-supplied shim the entire distance.

After every 2500 miles of towing, the space between the trunnion and the pressure plate should be checked.

If there is looseness here, the trailer will wobble even before belvedere washers are activated.

Even though the instructions only call for mild lubrication, you should nevertheless put a thin layer of lubricant in the sticking points.

A few things to keep in mind here if you find it difficult to latch the bars.

- Make sure that the trailer and the vehicle are sufficiently jacked up. It ensures that the bars are no longer under stress.

- When hanging freely, the bars should not be more than a maximum of two to three inches lower than the resting plate of the hitch.

If you fail to do so, the lift tool may have difficulty correctly grabbing the bars.

Thus, it will demand a significant amount of effort and time based on the scale of the required WD.

In addition to this, check to see that the trailer and the vehicle that pulls it are aligned as straight as is humanly possible.

When you will lift one bar, if there is an angle therein, it may cause it to shoot out.

Not only that – it will make it difficult or impossible for the other to launch up.

4. Husky hitch breakage:

Well, this doesn’t happen often and is very rare in its occurrence.

But if you should have yourself ready for it may happen anytime with a little deviation in the rated weight capacity.

Over the years, it has been revealed that many husky centerline hitch users come complaining that they have suddenly found their trunnion bolts on the passenger side broken.

And when this happens, as a cause-and-effect result, the passenger side top plates may be damaged.

Thus, it requires immediate replacement.

Reason for breakage:

It is often due to overloading – pure and simple.

But the most educated take here is that it is usually difficult to be that precise while loading and it may be a little here and there.

Unfortunately, only a little imbalance may lead to breakage.

Once the breakage occurs, you don’t really have many options left.

If a trunnion bolt is damaged or broken, it is highly likely that the wear and tear have already spread to the top plates.

Consequently, you might find all the top plates on the passenger side damaged.

So, the remaining trunnion bolts very often turn out to be of no use.

In instances, it often happens due to the failure of the Weight Distribution Hitch.

However weird it may sound, the weight distribution hitches, due to their own difficulties, may cause the Husky Hitch to suffer damage.

And due to unrestricted, and unaddressed sway, the bolts and top plates break down.

So, by all means, what we recommend you is that take the necessary preventive measure in the first place.

Solve the issue:

The only viable solution you have here is a precise check-up of the weight of weight capacity of the hitch at first.

You may get numerous other suggestions in this regard.

But what the Husky engineers and industry experts suggest is that you need “plotting and measuring the geometry” of the camper’s weights.

So, to do so, what you need is the camper’s weight. Hire a professional, and he will do the job for you.

Contacting the Husky engineers and helpline may also be a viable option.

Remember, knowing the camper’s weights is essential for plotting and measuring the geometry and running the analysis.

As to the weight distribution hitch, we have a straightforward piece of advice.

Whether you choose to take it or ignore it, we tell you to reject the weight distribution hitch and invest in a new one. Any unsuccessful WDH is useless and can’t be relied upon.

FAQs about husky centerline hitch problems:

Does The Husky Centerline Hitch Allow Reversing?

The Husky centerline hitch has an integrated sway control system, making backing up a breeze.

How many greases Should I Use In My Husky Centerline Weight Distribution Hitch?

Many weight distribution systems employ substantial friction to counteract rocking.

Husky does the same and makes a lot of noise because of this.

But you should not lubricate it excessively because doing so could remove the resistance to movement that friction provides.

Is It Safe To Sleep With The Husky Centerline Weight Hitch On All Night?

If you are within your vehicle’s towing capacity, you can safely leave your fifth wheel attached to your truck overnight.

Final Words:

Knowing the husky centerline hitch problems, and taking the preventive and protection measure beforehand can save you bucks! Remember, once damaged badly, it takes a lot of time and money in fixing it.

So, don’t let it go too bad to recover.

Keep the needed tools at hand and this article is your guide.

Also, leaving a comment will reach you to us for any further concerns!