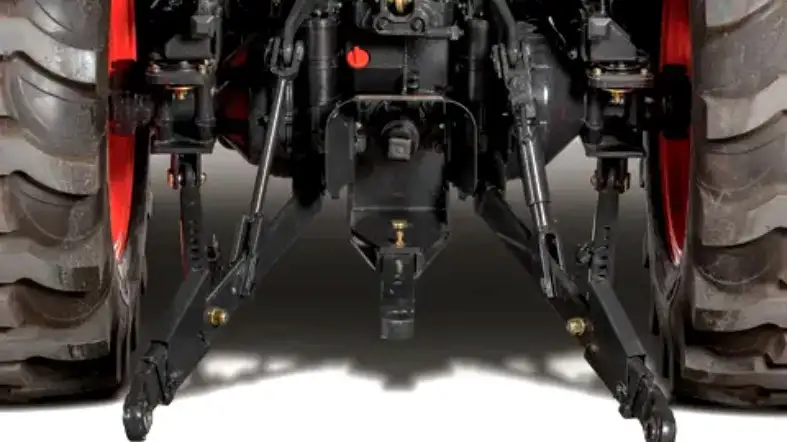

A 3 point hitch is an essential component of many farm equipment, used for attaching implements and attachments to your tractor.

If your 3 point hitch is swaying or shaking, it can cause problems with your equipment and make it difficult to use.

In this article, we will discuss the causes of 3 point hitch swaying, how to keep a 3 point hitch from swaying, and some prevention tips to keep your equipment working smoothly.

How To Keep A 3 Point Hitch From Swaying?

Here are a few tips to help keep your 3-point hitch from swaying:

1. Properly Adjust And Seat The Hitch

Make sure the hitch is properly adjusted and seated on the implement and the tractor.

A hitch that is not properly aligned or seated can cause swaying.

2. Use Stabilizers Or Braces

Use stabilizers or braces to help prevent swaying.

Some implements come with built-in stabilizers, or you can purchase aftermarket stabilizers that can be attached to the implement and tractor to help keep the hitch stable.

3. Adjust The Top Link Of The Hitch

Adjust the top link of the hitch to the proper length.

The top link should be adjusted to the right length to provide the correct amount of downward force on the implement.

If the top link is too long, it can cause the implement to sway.

4. Adjust The Lower Lift Arms

Use the lower lift arms of the hitch to provide additional stability.

The lower lift arms can be adjusted to provide an additional downward force on the implement, helping to keep it stable.

5. Slow Down On Rough Or Uneven Ground

Slow down when driving on rough or uneven ground.

Swaying is more likely to occur when driving on rough or uneven ground, so slowing down can help reduce the chances of swaying.

6. Use A Ballast Weight

Use a ballast weight on the front of the tractor.

Adding extra weight to the front of the tractor can help improve the stability of the hitch and reduce swaying.

7. Avoid Sudden Turns Or Changes In Direction

Avoid making sudden turns or changes in direction.

Sudden turns or changes in direction can cause the implement to sway.

So it’s important to make smooth, gradual turns when using a 3 point hitch.

Following these tips can help reduce the chances of your 3 point hitch swaying and keep your equipment and yourself safe while using it.

Now you know how to keep your 3-point hitch from swaying, but do you know why does it happen to you?

Why Does A 3-Point Hitch Sway?

A three-point hitch on a tractor can sway for a variety of reasons.

Some common reasons include:

1. Improper attachment of the hitch to the tractor:

The three point hitch is attached to the rear of the tractor using a series of pins and brackets.

If these pins and brackets are not properly aligned and secured, it can cause the hitch to move around, leading to swaying.

2. Uneven weight distribution:

The three point hitch is designed to support the weight of the implement that is attached to it.

If the weight of the implement is not evenly distributed, it can cause the hitch to sway.

For example, if the implement is longer on one side than the other, or if it has a heavy object mounted on one side, it can cause the hitch to sway.

3. Rough or uneven terrain:

If the ground is rough or uneven, it can cause the hitch to move around, leading to swaying.

This is because the tractor’s rear wheels will follow the contours of the ground, causing the hitch to move up and down as the tractor moves.

4. Improper use of the hitch:

The three point hitch is controlled by the operator of the tractor, who can raise and lower the hitch using hydraulic levers or levers.

If the operator raises or lowers the hitch too quickly, it can cause the hitch to sway.

5. Loose Bolts or Nuts

If any of the bolts or nuts on the 3 point hitch are loose, it can cause the hitch to sway.

This is why it is important to regularly check all of the bolts and nuts on the 3 point hitch and tighten them as needed.

6. Worn or damaged hitch components:

The three-point hitch consists of a series of pins, brackets, springs, and other components that work together to support the implementation and allow it to be raised and lowered.

If any of these components are worn or damaged, it can cause the hitch to move around, leading to swaying.

Now you know why three point hitch on a tractor sway. But are you sure your 3 point hitch is swaying?

Let’s check some of the key factors that can help you to determine if your 3 point hitch is swaying or not.

How To Determine If Your 3 Point Hitch Is Swaying?

1. Look for wear and tear

If you notice that your 3 point hitch is starting to show signs of wear and tear, it may be due to excessive swaying.

Look for cracks or breaks in the hitch, as well as any other damage that may have occurred.

2. Check The Bolts And Nuts

Another way to tell if your 3 point hitch is swaying is to check the bolts and nuts that hold it together.

If any of these are loose, it could cause the hitch to sway.

3. Look at the welds

If you see any cracks or breaks in the welds holding your 3 point hitch together, this could also be a sign that it is swaying.

4. Inspect the frame

If the frame of your 3 point hitch is bent or damaged in any way, this could be another indication that it is swaying.

5. Have someone else tow your vehicle

If you are not sure whether or not your 3 point hitch is swaying, you can have someone else tow your vehicle behind theirs while you observe from inside the cab.

FAQs on how to Keep A 3 Point Hitch From Swaying!

How Do I Reduce The Amount Of Sway In My 3 Point Hitch?

There are several things you can do to help reduce the amount of sway in your 3 point hitch, including regularly checking the bolts and nuts to ensure that they are tight, loading implements evenly, and replacing worn or damaged parts as needed.

Additionally, it is recommended that you have your 3 point hitch inspected by a professional mechanic on a regular basis

How Do I Fix A 3 Point Hitch That Is Too Loose?

If your 3 point hitch is too loose, you may need to replace the bolts and nuts that are holding it together.

You may also need to adjust the drawbar or install a new pin to help ensure that the 3 point hitch is secured tightly against the frame of your vehicle.

In some cases, you may need to have your 3 point hitch inspected by a professional mechanic to determine the exact cause of the looseness and the best course of action for correcting it.

How Can I Tell If My 3 Point Hitch Needs To Be Replaced?

If your 3 point hitch is swaying or showing other signs of wear and tear, it may need to be replaced.

Some common indicators that your 3 point hitch may need to be replaced include frequent rattling or shaking while you are using it, uneven weight distribution while attaching implements, or a visibly damaged frame.

What Are Some Common Problems With 3 Point Hitches?

Some common problems with 3 point hitches can include swaying, uneven weight distribution, worn or damaged parts, and loose bolts or nuts.

To help prevent these issues and ensure the proper functioning of your 3 point hitch, it is important to regularly check all parts of the hitch for wear and tear and make any necessary adjustments or repairs as needed.

Final Thoughts

It is important to know how to keep a 3 point hitch from swaying in order to prevent further damage or safety concerns.

There are several things you can do to help reduce the amount of sway in your 3 point hitch, including checking the bolts and nuts regularly, loading implements evenly, and replacing worn or damaged parts as needed.

Follow these tips to help keep your 3 point hitch from swaying and causing further damage or safety concerns.