Weight distribution bars are vital for assuring safety while towing a vehicle on the road.

Their primary function is to regulate the mass of the vehicle you’re towing behind, ensuring that the trailer doesn’t tip over.

But how tight should weight distribution bars be?

Well, that’s something that confuses most people in the first instance.

But here we here are to help you out in this regard.

Let’s tighten your weight distribution bars safely.

How tight should weight distribution be?

Weight distribution should be tight and evenly distributed in order to ensure safe and stable towing.

This means that the weight of the trailer and its load should be distributed as evenly as possible between the front and rear axles of the towing vehicle.

Ideally, the weight distribution should be such that the tongue weight (the weight of the trailer at the point where it connects to the hitch) is between 10-15% of the total weight of the trailer and its load.

This will help to prevent sway and ensure that the towing vehicle has proper control and stability while on the road.

Weight distribution bars:

To accommodate the often-convoluted physics involved in hauling a trailer, we have the weight distribution bars.

While towing, you must keep in mind the towing vehicle’s weight capacity so that you don’t overload it.

You must stay below those limits at any cost.

In addition to this, it is essential to ensure that the weight of the trailer is evenly distributed throughout its interior.

It ensures that the bars carry a proportionate amount of weight on the front and on the back.

There should not be a substantial load in the front while being empty in the back or the opposite.

If you maintain this level of awareness, it assists in maintaining the level and stability of your trailer in the best feasible manner.

Why Is A Weight Distribution Bar Necessary?

Towing requires a coupling.

These bars are a component of that coupling.

Every person planning to tow has to be careful about this hitching and coupling equipment.

Whatever you use in the process of pulling the trailer should be of a high standard, robust, and long-lasting.

It will guarantee that the trailer will remain attached during the pulling process regardless of the conditions.

So, if you want to take a safe stand here, you should opt to use weight distribution bars.

Functions of weight distribution bars:

Before you begin towing, you make sure that everything is fine and that you are set to move on.

But, what takes care of the system when you are towing?

It is the responsibility of the weight distribution bars to ensure the continued maintenance of safety and stability.

They serve as a kind of fallback plan, which gives them an edge over other equipment.

They are able to do this by disbursing the weight in an even manner across the hitch coupling and the vehicles.

Because of this, everything remains stable.

There is also no risk of the front of the trailer leaning to one side as the vehicle travels down the road.

Working Process Of Weight Distribution Bars:

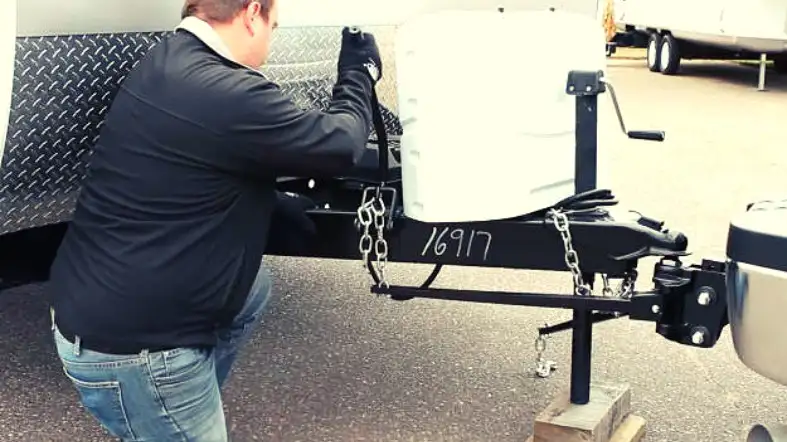

In this process, we actually use spring bars.

We set up those spring bars in-between the trailer we pull and the towing vehicle.

How much tension the bars are able to apply to the frame of the trailer?

It all depends on how tightly they are tied.

Because of this, the back of the trailer is given a very tiny upward lift.

It acts as a counterbalance to the inherent downward pressure that is exerted on the trailer as a result of the entire weight being concentrated on the front.

Too loose vs too tight bars:

If it is not tight enough, it will not be able to counteract the pressure that is being applied from the front.

If it is overly tight, it will not allow for much flexibility in the forward movement.

Thus, it will cause the trailer to be rigid.

Bars save you a lot of trouble:

Notwithstanding this, the weight distribution bars will help keep your vehicle and trailer free from a great deal of trouble.

If you do not have it, there would be nothing preventing the weight of your trailer from pressing down to the back.

The enormous pressure on the back may eventually off-balance the vehicle.

This will also lead to extra towing time.

Because of the extra time, numerous components of the car will have to bear a significant amount of stress.

The axles, the brakes, in fact, the steering could be in jeopardy.

Inaccurate tightness and consequences:

This control lapse could result in a hazardous collision regardless of whether or not the vehicle was pulling a trailer.

In actuality, it is a rather time-consuming and laborious process to determine the required tightness of the bars.

No matter how tedious a process it is, you will still have to do it to ensure safety.

How do you do it then?

While tightening the bars, you will have to consider a few things at the same time. Let’s help you with that right now.

When To Tighten The Weight Distribution Bars?

Experts do usually point out a number of warning signs to ensure safety with weight distribution bars tightness.

If you are careful here, you can easily predict when you have to tighten the bars and how much to tighten.

Higher speed:

The first scenario is one in which you are aware that you will be traveling at speeds that are far higher than the ordinary.

This will raise the risk that your trailer will sway and will make it more susceptible to the effects of wind.

Taking preventative measures in advance is critical here.

So, strengthening the weight distribution bars in advance can help mitigate the effects of any potential problems.

Potentially unfriendly route:

The next consideration is the route that you will travel.

If you already know that the route you will be traveling will have roads that are not level and bumpy.

The roads could also be very slick or have very little or no pavement.

Every one of these factors might also lead to a significant decrease in the trailer’s level of stability.

Timely Adjustment Of The Bars:

If you’ve owned your trailer for a while, there’s one important factor you should consider.

Ask yourself this: when did you tweak the weight distribution bars for the last time?

If it’s been more than a year, you should do it.

It’s essential since they could get looser all by themselves after some amount of time has passed.

Particularly when you are an ardent traveler, it becomes more significant.

You might have gone on a number of excursions alongside the trailer over the course of the previous year.

So, it is very likely that the weight distribution bars need tightening.

It is possible that based on a few other factors, your weight distribution bars will need frequent re-adjustment.

For instance, depending on the frequency with which you engage in off-road activities, you will have to adjust it frequently.

Also, how often you experience severe weather conditions will have an effect.

Weird noises:

There could be instances when the hitching of the weight distribution bars produces strange noises.

This could be another sign that you need to inspect the weight distribution bars on your trailer.

When you turn your vehicle, for example, any sort of squeaking noise could be a red sign.

This warning sign indicates that any section of the hitch is malfunctioning.

In fact, the weight distribution bars can be broken down.

The thumb rule:

After every one thousand miles, as a general rule of thumb, it’s a good idea to check in with your weight distribution bars.

It helps to make sure they’re still in excellent working order.

In fact, it doesn’t only help with tightening them once again, but also with their cleanliness.

You get to whether they are clean and in excellent condition.

You also get to make sure that they have not suffered any harm in the process of towing.

Always keep in mind that the weight distribution bars play a significant role in maintaining the structural integrity of your trailer.

When it comes to ensuring the safety of both you and your trailer while out on the road, one of the most important things you can do is check the condition of these items.

In most cases, this occurs well before the problem becomes severe enough to cause the vehicle to lose its stability while traveling down the road.

Consequently, you should make it a priority to act in response to this cautionary signal. Whenever any warning shows up, act prudently.

Things To Keep In Mind Before You Tighten The Bars:

The first thing to do is to change the intensity of the spring bars and yoke hook links.

You can either strengthen it or weaken it.

The lift chains interact with the spring bar arms.

Due to this, the bars get the needed upward force.

It transfers the hitch’s load to the front wheels.

The upward force is a direct result of the number of links.

So, if the situation requires less force, you have to increase the links.

On the other hand, decreasing the links will give more upward force.

You have to first deal with the mount head ball’s tilt if you need as few as 5 or (less than that) links.

So, this is the second important thing to keep in mind.

To do this, you need to disconnect the tow vehicle’s trailer and drive it.

Then, hitch the head carefully without the top bolt.

Then, you can find the spacer rod. Shift the angle by adding or removing the washer from there.

Finally, make an effort to adjust the height as described in the manufacturer’s instructions.

Before you tighten the weight distribution bars, these are the most crucial considerations to keep in mind.

FAQs about how tight should weight distribution bars be

What If The Weight Distribution Hitch Is Too Tight?

This will affect the mobility of the vehicle.

So, the rising pressure on various equipment and vehicle component can lead to serious accidents.

Can I Travel With Loose Weight Distribution Bars?

You should not travel with loose bars as it concerns safety issues.

It may lead to uncontrollable sway and potentially dangerous accidents.

Can You Put Too Much Tension On Weight Distribution Bars?

There is a limit to how much tension you can put on it.

Experts suggest staying within that prescribed limit.

Final Words:

So, we can conclude that how tight the weight distribution bars should be is always dependent on various factors affecting the capability of the bars.

However, it should never be too loose to sway uncontrollably or too tight to make the vehicle rigid.

Always look for red signs as discussed before, to endure utmost tightness and safety.