It is true that you might have faced or are about to face some common john Deere 3 point hitch problems.

But it can be difficult to find comprehensive data on this online.

Thus, it is best if you don’t invest any unnecessary effort or time into this.

To save you time in your research, we have amassed every available data vis-a-vis John Deere 3 Point Hitch problem.

In this article, let’s have a discussion about the issues and fixes associated with the John Deere three-point hitch.

John Deere 3 point hitch problems:

The common problems that you are going to face with a John Deere 3-point hitch are lifting problems, hydraulic problems, top link problems, draft control problems, hitch adjustment, pressure issues, etc.

Moreover, the hitch breaks down sometimes, which in itself is a problem and requires fixes.

The 3-point hitch doesn’t lift:

This is one of the basic issues we get to face while operating a John Deere 3-point hitch.

So, instead of panicking and beating around the bus, knowing the science of it can move the hill for you.

There are a few potential explanations for why the lift on your three-point hitch isn’t working properly.

1. Not enough hydraulic fluid:

The amount of hydraulic fluid should be the first component to be checked.

If there is not enough fluid in the system, the fluid cannot put enough pressure on the system.

And the consequences?

The hitch will not be able to be lifted for the lack of pressure.

2. Jammed/damaged lift arm or hydraulic cylinder:

There is a considerable possibility that the lift arm itself or the hydraulic cylinder has been damaged or is jammed.

In case the cylinder is damaged in any way, you will need to purchase a replacement for it.

On the other hand, if the lift arm has frozen solid, you could try thawing it with a heat gun in the first place.

3. The 3-point hitch itself is faulty:

One final possibility is that the fault lies within the 3-point hitch itself.

You will require a new trap if the one you have is damaged in any way, including being smashed or twisted.

Issues With The Pressure Control:

Sometimes the excessive pressure issues on a 3-point hitch strike unwanted and unnoticed.

But if you discover that your John Deere 3-point hitch is exerting an excessive amount of pressure on your tractor, you get to try a few solutions each of which may relieve some of that pressure.

1. Customize the pressure settings:

Though it’s not viable in most cases, it is worth a try.

A great number of hitches nowadays comes equipped with pressure settings.

So, you can adjust them for the pressure to be lowered.

The manual of the 3-point hitch will direct you on this.

So, check the owner’s manual to determine whether there are any options for customization of the trap.

2. Add more weight:

However odd it may sound, it is something that industry experts reliably suggest.

In case the 3-point hitch does feature a pressure setting that you may modify, start putting extra weight on it, which in turn can reduce the pressure.

Adding extra weight assists in spreading out the weight of the hitch more evenly across the hitch.

Consequently, it lessens the stress that the hitch was bearing all alone.

3. Raise the drawbar:

Another viable alternative is to lift the drawbar to a higher position.

It will reduce the pressure like a walk in the park.

As an additional benefit of this, the hitch won’t be able to dig into the ground.

4. Lubricate the trap:

Last but not the least, the trap must remain thoroughly lubricated to function properly.

When properly lubricated, it significantly cuts down the amount of friction thus decreasing the overall pressure considerably.

Adjustment Issues With The John Deere 3-Point Hitch:

Having problems with the adjustment system is not unusual at all.

Not too common though, you may end up tiring all your energy into fixing this if you don’t know the tricks here.

1. Three additional adjustment positions:

The tractor is attached to the hitch at three separate spots along the length of each arm.

Moreover, there are three more points of attachment between the arms and the gadget.

So, this is the crux of all if you want to ensure a perfect adjustment.

If you are having issues with adjustment, just keep in mind that these adjustment points allow for vertical and horizontal adjustment.

Another fix to this problem lies in the three-point hitches on John Deere tractors being adjustable.

So, while in the driver’s seat, without leaving the seat, you can mount and dismount the implements.

2. The trap control:

The trap consists of three arms that are all attached to the tractor in different ways.

The arms’ multiple points of attachment to the tool allow for lateral and vertical adjustment.

3. The simple solution:

Before you can make any adjustments to the trap, the arms have to be brought up to their highest position.

After that, you are responsible for turning the adjustment knobs that lie at the edge of every component counterclockwise.

Then set the art in your desired position and turn the knob to make it snugger.

In the final step, you have to bring the arms to a position that enables them to aid in the implementation.

The Hydraulic Problem:

If you possess a John Deere, then you are aware that the construction of this tractor is comparable to that of a tank. Its robust construction can withstand a lot of abuse.

However, even the most powerful machines sometimes experience difficulties, and a John Deere 3-point hitch is not an exception to this rule.

So, this hitch may trouble you with hydraulic issues sometimes.

If you’re having trouble with your hydraulics, you should start by making sure the fluid levels are adequate.

When the fluid level drops too low, it’s time to refill. Make sure you’re using the proper fluid, too.

If you don’t know already, for its gearbox and hydraulics, John Deere functions most efficiently with Hy-Gard oil.

After making sure the fluid levels are adequate, you should inspect the hoses and connections for any signs of leaks.

Even a minor one might lead to more serious issues later on. The sooner a leak is fixed, the better.

Note: Mechanical issues can be difficult to diagnose and fix on your own.

So, if your hydraulics are still giving you trouble, it’s time to get help from a qualified technician.

John Deere provides access to technicians who have received extensive training from the company itself.

So, they are, therefore, well-equipped to identify and resolve any issues with your tractor and hitch.

Draft control issues:

When the three-point hitch load shifts as a result of shifting conditions in the soil, the hitch float also has to do its job.

But, when the hitch has issues with its draft control, it fails to control the pull of the hitch effectively.

It doesn’t lower or go higher with the varying soil conditions to deal with. Thus, the tractor will fail to maintain the pull at the same level.

So, the solution lies in the three-point hitch float and driver’s control.

When the position control lever is at its bottom, the implement pull control light pops up. Then, you have to utilize the draft control lever manually to implement the pull.

Adjust Your John Deere 3-Point Hitch Like A Pro:

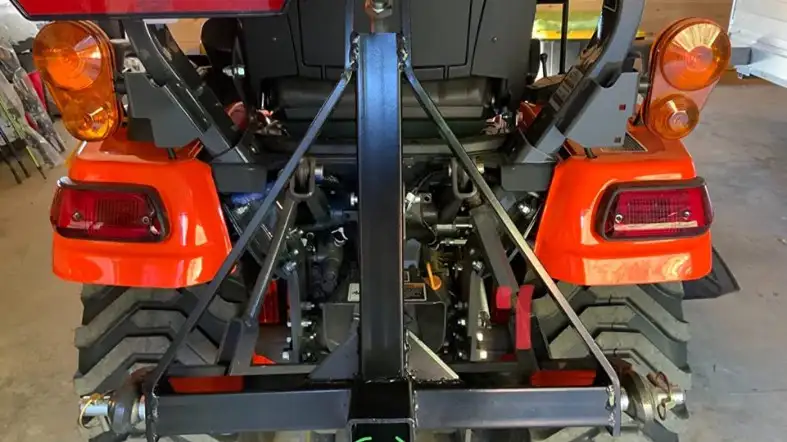

With the three-point hitch on your John Deere tractor, you can pull and operate a wide variety of implements.

The basic science of a perfect adjustment hides in the three arms of the trap.

The stabilizer bar remains the focal point of attention, while the upper link, the lower link functions as the other two arms.

Two hydraulic cylinders are responsible for raising and lowering the arms.

A pin secures the components of the tractor.

On the other hand, the hitch utilizes a clevis to secure the tool to the arms of the tractor.

Step 1:

To begin with, you have to set the hitch arms to their highest possible before assembling a tool on the three-point hitch.

Step 2:

The next step is to reverse the direction of the tractor immediately.

Keep pushing back until the device’s hitch points are below the lower link arms.

Step 3:

After that, reduce the height of the arms to make sure the lower link arms are lying on the tool’s hitch points.

Step 4:

Now, insert the clevis pins into the lower link arms’ corresponding slots.

And, in the same way, into the tool’s corresponding hitch points.

The biggest advantage here is that you get the hydraulic levers that control the three-point hitch just beside the driver’s seat, on the right-hand side.

To control the left-side hydraulic cylinder, you get a control lever on the left side.

For the control of the right-side hydraulic cylinder, there is a control lever on the right side as well.

So, the alignment here makes it easy to understand the functioning if you pay a little attention.

To pull up the arms, pull the levers in the direction of your forward motion.

To bring down the arms, you just need to pull the levers in the opposite direction.

FAQs about john Deere 3 point hitch problems

Does John Deere’s 3-Point Hitch Have Down Pressure?

Yes, the right-fender rocker switch activates the downforce.

When the cylinders are activated, it causes the cylinder arm to retract and holds down the hitch arms to increase the downward force.

What Causes A John Deere 3-Point Hitch To Bind?

Too long lower link arms cause it. Because of this, raising or lowering the hitch becomes difficult.

Cutting off around an inch from the arm’s length is the fix.

Is too short a top link a problem?

Yes, the hitch will be unsteady and sway in the wind. It can be fixed by adding a six-inch extension to the top link.

What Problem Does A Short PTO Shaft Cause?

It won’t let the PTO be engaged or disengaged. If you try, by force, the hitch will be stuck.

A PTO shaft extension of around four inches will solve the problem.

Final Words:

In an attempt to solve the John Deere 3 point hitch problems, we have double-checked these details with multiple John Deere 3-point hitches.

We sought expert advice from the John Deere 3-point hitch associates and reps.

If you put these suggestions into practice, you should find it easier and less stressful to use your 3-point hitch.

So, work with this article and cause yourself less anxiety. Yet, for further concern, you only need to leave a comment below.